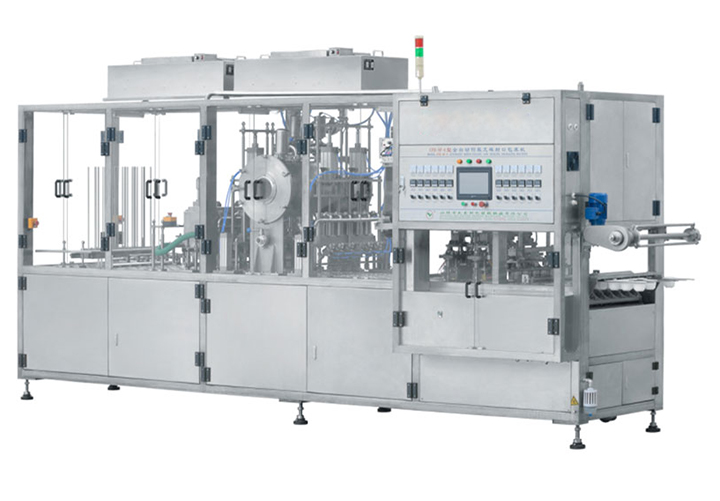

Automatic Yogurt Cup Filling and Sealing Machine Manufacturers

Enquiry Now!Automatic Beverage Packaging Liquid Cup Yogurt/Drinks/Seriflux/Jelly/Chocolate/Biscuits/Cookie/Cream/Cheese Filling And Sealing Machine Manufacturers

Technical Requirements

The yogurt filling machine can meet the requirements of normal temperature and low temperature yogurt filling production, the capacity of a single cup is about 150-200 grams, the speed of the machine can be adjusted within 18~20 mold/minute; Yield 7000 ~ 8500 cups/hour.

1.Automatic drop cup;

2.The filling device adopts the special material barrel for dairy products for strong filling and meets the design requirements of CIP cleaning. The flow regulation is installed on the upper part. The glass observation holes are installed on both sides, and the action time of the filling valve is adjustable. The filling velocity is appropriate and the bubbles are few. Equipped with stainless steel Angle seat valve pneumatic level detection needle level control;

3.Adopt two sealing, flat sealing + linear sealing, sealing temperature, pressure, time is adjustable; The head assembly adopts floating connection, the head structure adopts spring buffer type, and guarantees the sealing pressure balance, the head assembly adopts the template positioning pin type sealing, sealing strength meets the requirements of Party A; All materials of the press head assembly need anti-rust treatment;

4.The cutter assembly is made of stainless steel and connected by floating assembly. The cutter assembly is made of four-guide pin type with template. The axial contour of the cutting edge is similar to the shape of the template cutter groove. The cover film is automatically modified and corrected in the forward direction; Equipped with Omron color standard detection electronic eye components, and the use of screw adjustment before and after, up and down position; In the correction action control mode, it can be automatically corrected or manually corrected. Suitable safety protection devices shall be designed and installed at the pressure head, cutter and formwork turning.

5.Cylinder mounting plate strength is sufficient; The transverse tensile strength of the frame plate at the support of the head frame plate is sufficient (with strengthening plate), and there is no deformation in the life period; Head frame plate should avoid oil and other dripping;

6.The template uses solid acid and alkali resistant and rust resistant aluminum, and the drainage through hole is processed and cleaned at the inflection point of the cutter groove. Install according to the movement direction of the die-cutting drawing, and Party B shall provide the template die-cutting drawing;

7.The template support of sealing and shearing is made of special engineering plastics, and the parallelism and flatness are adjustable. The upper and lower positions of the template chain guide rail are adjustable.

8.The template drive system adopts Taiwan brand servo motor, worm gear and worm reducer stepping mechanism, equipped with overload torsional limber; Stainless steel sprocket, shaft, bearing and bearing seat, transmission chain (widened double chain), transmission belt tension adjustable;

9.The pressure one pressure two temperature control system adopts digital display temperature control, solid state relay, and electric heating tube disconnection alarm;

10.Electric control system components use Schneider brand products, electric control box for stainless steel waterproof design, electric control box wiring, marking neat standard. The machine adopts Japan Mitsubishi PLC+ touch screen mechanism for logic control; Panel control switch design, reasonable layout, easy to operate.

11.Press head assembly, cutter assembly relative template using pin positioning; Press a flat sealing head torus, press two pressure head line sealing and template sealing platform; The positioning of cutter and template satisfies the widest and narrowest of the round edge of the product cover film;

12.The frame is a 160*80 SUS304 stainless steel square tube, supported by 6 feet, and the parts below the head frame plate (including the indenter cutter assembly, chain guide support, and adjustment parts) are all made of anti-rust materials. The total length of the frame is about 5 meters, and the width is 1500mm+20mm; the frame has a reasonable structure and sufficient strength, and the visual error is horizontal and vertical without sensory error. The 6 feet are equipped with detachable casters. Equipped with an ejection and extraction mechanism, the cup-shaped filling product can be reliably taken out; the air intake of the whole machine is equipped with a suitable flow of air source triplet for filtering, pressure regulation, and lubrication, and the installation position avoids secondary pollution of the product. A receiving tray is installed under the frame to collect cleaning water and material liquid for centralized discharge.

13.The pneumatic components for the pressure head and the cutter adopt brand products (Taiwan Airtac), and the solenoid valve is installed outwards for easy maintenance; the gas return air is collected and filtered and discharged;

14.The left and right positions of the film release rod are adjusted by handwheels. Before heat-sealing, a double guide film rod anti-pressure hand structure is adopted. The cutting rear end is equipped with a double rod cup and waste film separation rod. The film has a quick disassembly structure, and the friction force of the rewinding drive friction plate can ensure the reliable rewinding of the waste film;

15.The dairy filling system meets the filling requirements of normal and low temperature dairy products. The filling barrel is designed to be sanitary and without dead ends.

16.Equipped with independent cup pressing rods, a single diameter coincides with the edge of the cup, the cup pressing axis positioning frame adopts an open type, which can float and go up and down smoothly, and the installation position is at the front end of the blanking;

17.CIP cleaning system, independent and automatic CIP cleaning cycle of the filling system in non-production state; It is required that the cleaning shower is centralized, and the effective spray intensity is fully covered;

18.The whole machine adopts three-phase 380v power supply, and the working air source pressure is 0.5~0.8mpa.

19.The whole machine is equipped with plexiglass machine cover, and the air filter device is installed on the top (reaching the requirement of 100,000 grade clean)

Environmental Requirement

The design, manufacture, installation and commissioning of the equipment and the entire system provided by Party A shall comply with relevant national standards and regulations on safety, environmental protection, food hygiene, etc., free of chemical, foreign matter, personal safety hazards, and easy to operate and maintain.

Photos