High-speed Automatic Liquid Yogurt Filling and Capping Machine for Glass Jars/Plastic Cups

Enquiry Now!1. 6-Head Automatic Filling Machine

This machine is a fully automatic intelligent servo piston filling machine, which is widely used in the quantitative filling of liquid materials such as edible oil, lubricating oil, sesame butter, peanut butter, tomato sauce, chili sauce, jam paste, etc. This machine adopts advanced computer programming control PLC (PLC), servo motor, servo drive, and sensors imported from Korea make the operation easy, fast and accurate. Full-color touch screen human-machine interface, the whole filling process can be completed by setting the filling volume and the number of filling heads through the touch screen on the equipment and automatic filling, and the process basically realizes one-button operation.

All parts in contact with materials are made of 304 food-grade stainless steel, which meets food hygiene standards.

Using the principle of piston filling, the filling speed is fast and the accuracy is high. The special filling valve ensures the cleanliness of the filling process.

Linear transmission, easy to adjust.

The unique advantages of this machine:

1.Advanced Smart Operating System

With the support of advanced PLC software, the servo motor, servo driver and volume adjustment only need to set the target volume on the touch screen, and the equipment can automatically increase or decrease to reach the target volume. Color touch display, all operations, monitoring and other functions can be completed on the touch screen.

2. Wide application range and easy adjustment

Suitable for filling most bottle types (especially special-shaped bottles), easy to adjust the volume

Features:

1. The frequency conversion speed regulation conveying system can be adjusted according to the production speed; (length can be customized according to customer requirements)

2. The whole machine is made of SUS304 material, with beautiful appearance, high filling accuracy, convenient adjustment, safety, and easy operation.

3. High-precision piston metering device, accurate and reliable quantification, convenient and quick to adjust the filling volume by numerical control;

4. Imported sealing device is adopted, and effective anti-drip measures are added to ensure that there is no dripping on site;

5. The equipment comes with a storage box, which is equipped with stirring, and the pipeline is cleaned independently, which is convenient for cleaning.

6. The filling head is equipped with a Japanese Panasonic photoelectric system, which can accurately identify the positioning of the filling bottle and realize bottle filling and no bottle filling.

Technical parameter

1. Filling range:3L/2L

2. Filling speed: 800 bottles/hour

3. Measuring accuracy: ±1%g-±2%g

4. Rated voltage: 3-phase 380v

5. Rated power: about 3.2Kw

Detailed Pictures

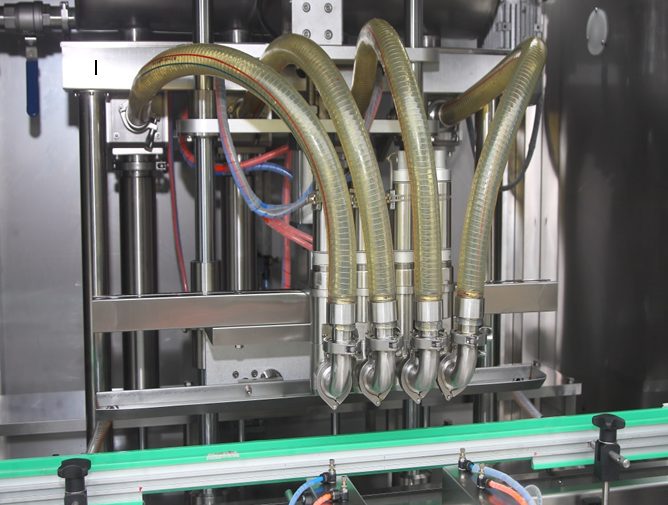

Filling Part

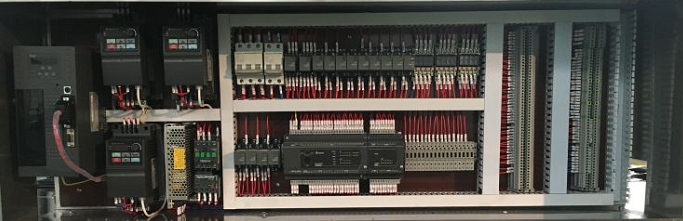

Control Part

Part of the material box

Main configuration list of electrical components

| No | Name | Brand |

| 1 | PLC | Wecon |

| 2 | touch screen | Wecon |

| 3 | servo motor | Haide |

| 4 | server Driver | Haide |

| 5 | Low voltage electrical appliances | DELIXI |

| 6 | Pneumatic ball valve (or self-made steering valve) | KST |

| 7 | photoelectric | Jujia |

| 8 | The electromagnetic valve | TKC |

| 9 | cylinder | Conson |

| 10 | conveyor motor | Sanli |

| 11 | Filling valve | Self-made |

2.Cap Feeding Machine

Lifting cap sorting machine, also called automatic cap sorting machine, cap sorting and placing machine, is a special equipment for automatic cap sorting and capping. It is mainly used in the supporting equipment of filling line. The main function is to automatically sort and place caps.

Lifting cap sorting machine, also called automatic cap sorting machine, cap sorting and placing machine, is a special equipment for automatic cap sorting and capping. It is mainly used in the supporting equipment of filling line. The main function is to automatically sort and place caps.

The cap sorting system mainly adopts a straight-line belt conveying device to realize the purpose of cap sorting; the support system supports the vertical cap lifting system, and can adjust the inclination of the cap lifting system belt, so as to adapt to the bottle caps of different heights. The need for cap sorting; the cap dropping system makes the bottle cap accurately fall on the bottle mouth through the arc-shaped guide rail, so as to achieve the perfect combination with the fully automatic crawler capping machine. This equipment has the characteristics of simple and reasonable structure, good automation, no need to climb for replenishment and capping, and convenient operation.

3.Fully Automatic Capping Machine

This machine is suitable for the screwing and sealing process of plastic bottle screw caps. It has perfect performance, convenient operation and easy maintenance. It is widely used in daily chemicals, wine, food, beverages, chemicals, reagents, pesticides, etc. to the automatic packaging line and water line.

After the bottle in the previous process is filled, the conveyor automatically enters the machine for capping. When the bottle enters the capping machine, the machine has two sides to clamp the bottle and transport it to the rubbing and capping station. The machine has a photoelectric sensor system. Rub the cover, which greatly increases the stability and working efficiency of the machine.

Technical Parameter

1.Sealing bottle height (mm): Customize according to the actual bottle

2. Adapt to cover diameter (mm): Customize according to the actual bottle

3. Adapt to bottle diameter (mm): Customize according to the actual bottle

4. Weight: 350kg

5. Output (bottles/hour): 500-1800BPH

7. Dimensions: (L×W×H) (mm): 1000*950*1800mm

4.Automatic 304 Stainless Steel Conveyor Belt

It is mainly composed of chain belt and frequency conversion speed control device, and the conveyor chain is composed of 304 stainless steel chain belt. The speed of conveying is adjustable, which reduces the labor intensity of manual handling and realizes the automation of production.

The main technical parameters:

1. Conveyor belt width: 82.6mm

2. Conveying speed: 2~6m/s

3. Rated voltage: 3-phase 380v

4. Speed control system: frequency conversion speed control

5. Machine weight: about 210kg

6. Height from the ground: 850mm+50mm (can be made according to customer requirements)

7. Chain belt material: SUS304 stainless steel

8. Working direction: from left to right (left in and right out)