XCMG XZ680A Horizontal Directional Drilling Hdd Rig

Enquiry Now!XZ680A Horizontal Directional Drilling Rig

Technical Specification

The advantages of XZ680A horizontal directional drilling

1. The rack pinion push and pull. The transmission is smooth and reliable. The power head spindle floating improve the service life of drill pipe thread;

2. The line-control proportion of walking system ensures the security of the walk;

3. The slurry flow shift stepless speed regulation system is more convenient to adjust the flow of the slurry, save the slurry and reduce the environmental pollution caused by slurry flowing;

4. The push-pull pressure shift stepless speed regulation system adjusts the push-pull pressure according to different working conditions, fast and convenient, which also can protect the drill pipe thread from being damaged.

5. 45 ° rotating cabin can be realized, which make the tractor driver in driving indoor observe the vice action more conveniently. At the meantime, it improves the interior assembly and increases the radio audio and USB port and improve operation comfort.

Catalog

1.The introduction of the technology

2. The main technical parameters

3. The main parts subsidiary

4. The whole machine appearance and transportation

5. The accessory technical documents

1. Technical specification

Product model: XZ680A horizontal directional drilling

Manufacturer: XCMG GROUP

XZ680A horizontal directional drilling is one-piece full load type design, which adopt the hydraulic pilot control and load sensitive control and a number of advanced control technology and the company’s proprietary technology. The main performance parameters and control technology has reached the domestic advanced level. Hydraulic system, transmission system, reducer, electric control system and other main components choose the brand name products at home and abroad. The quality is reliable.

One.The introduction of the technology

1.1 Chassis

Using steel tracks, South Korea Tongmyong walking speed reducer, traction, venue adaptable, stable and reliable performance.

Chain tread 3165 mm

Track Shoe Length 3930 mm

gauge of tracks 1825 mm

Creeper tread width 450 mm

Roller number 7 piece×2

Walking speed reducer South Korea Tongmyong TM22VC×2

Driving force 123kN

Climbing Capacity 30%

Walking speed 2.5km/h

Ground pressure 67kPa

The total quality of work 21T

1.2 The engine system

The Dongfeng Cummins engine inter-cooled turbocharged. Emissions meet the emission standards II and electronically- control throttle.

Engine Model 6LTAA8.9-C325

Rated power 239kW

Maximum engine torque 1230 N·m /(1400r/min)

Rated rotor speed 2200 r/min

Meet the emission standard standards II

Fuel tank capcity 425L

1.3 The hydraulic system

Using the load sensitive control, constant power system, pressure to cut off, the electro-hydraulic proportional control and several advanced control technologies. The imported components, which is reliable in quality.

Triple main pump SAUER H1P-130+ ER100B+ FR074B

Manual reset relay AMCA APV-22 + APV-22

Slurry pump valve AMCA APV-22

Oil Tank Capacity 750L

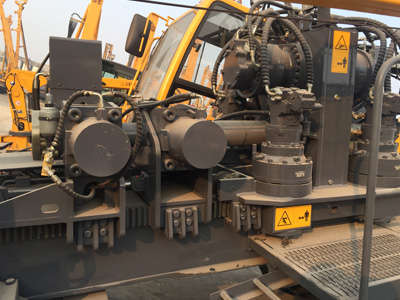

1.4 Power head

Push and pull a drill through the gear rack and complete. Power head spindle floating device effectively protect drill pipe thread. Variable motor can achieve high-speed push and pull. Push pull size can be adjusted according to the requirements of the construction, the protection of the drill pipe.

Power head rotation system

Rotating system flow 277L/min

Pressure 270bar

Motor Huade A6V107×2

Reduction box Brevini 2×ED2090/Bonfiglioli 2×307L2

Maximum swivel torque 28250Nm(Option)

Maximum rotative speed 100r/min

Power head push and pull system

Push and pull system flow 371L/min

Pressure 260bar

Manual reset relay AMCA APV-22/SAUER PVG100

Motor Huade A6V107×4

Reduction box Brevini 2×ED2090/Bonfiglioli 2×307L2

The biggest push pull 725kN

The biggest push and pull speed 32m/min

Maximum swivel torque 28250N·m

The maximum stroke power head 6600mm

1.5 Electrical system

In view of the horizontal directional drilling construction technology, the application of advanced intelligent control technology, CAN bus technology, using imported high reliability of the controller. To optimize the display in the instrument location, use the larger instrument, easy to observe. Walking wire control can realize stepless speed regulation, safe and convenient operation.

System Voltage DC24V

Controller Rexroth RC28-14

Push and pull rotation handle SAUER MCH22

1.6 Drill stand

High strength alloy steel drill stand and slide drilling. Angle adjustment is convenient.

Drill sliding distance 2500 mm

Drill stand Angle adjustment 10~18°

1.7 Vice

Rig is equipped with powerful shackle vise. Front and rear vice are relatively easy- slip. It is easy to replace canine teeth of maintenance.

Clamp force 1120kN

Maximum shackle torque 58900N·m

Rear vice rotation Angle 25°

Vice sliding distance 200mm

1.8 The slurry pump system

For construction of Hengyang slurry pump equipped with mud and slurry, which guarantee the construction smoothly. There are four adjustable gear speed which can also be adjusted the flow of the slurry pump and provide better operating experience.

Gear 4 speed

The maximum flow of slurry 600L/min

The maximum pressure of slurry 100bar

1.9 Cab

Rotating control cab, adjustable seats, equipped with air conditioning, greatly improved the operation comfort level of drilling rig, interior lights, windshield wipers, the front glass can be doubled.

Width of the cabin 1000mm

Length of the cabin 1800mm

The rotation angle 45°

1.10 Lorry crane

Random configuration 2T XCMG lorry crane and manual operation stable.

Model GSQ2SK1Q

Max lifting weight 2T

The farthest distance operation 5.67m

Max. Lifting Moment 4T·m

2.The main technical parameters

| Item | Technical parameters | |

| Engine | Producer | Cummins Engine CO.,Ltd |

| Model | 6LTAA8.9-C325 | |

| Rated power | 239 kW / 2200 r/min | |

| Power head push and pull | Type | Pinion and rack drive |

| Rated pulling/feeding force | 725/725 kN | |

| Running speed of power unit | 0~32 m/min | |

| Rotation | Type | Double-motor gear transmission |

| Max.torque of power unit | 28250 N·m | |

| Rotation speed of power unit | 100 r/min | |

| Drill stem | Diameter | φ102 mm |

| Length (single piece) | 6000mm | |

| Adjustment angle | 10~18° | |

| Travel Driving | Type | Self-propelled steel tracks |

| Travel speed | 2.5 km/h | |

| Slurry pump | Type | 600L/min,hydraulic drive |

| Total weight | 21T | |

| Dimensions | 11610×2800×3115mm | |

3.The main parts subsidiary

3.1 The core parts subsidiary

| Name | Manufacturer |

| Engine | Dongfeng Cummins Engine |

| Main pump | SAUER |

| Auxiliary pump | Tianjin |

| Manual reset relay | SAUER/AMCA |

| Hand shank | SAUER |

| Controller | German Rexroth |

| Power head motor | Beijing Huade |

| Power head speed reducer | Bonfiglioli/Brevini |

| Power head bearing | ZWZ |

| Lorry-mounted crane | XCMG GROUP |

| Track | Hubei Xian Group |

| Walking motor, reducer | South Korea Tongmyong Copmay |

3.2The options are as follows (With reference to the contract)

1) Drill stem:

| Name | Type | Specification | Remarks |

| Drill stem | Welded type(S135) | ¢102mm×6m | NC38Clasp Type |

2) Back to the expansion device:

| Name | Type | Specification | Remarks |

| Back to the expansion device | Squeeze expanding type | ¢450mm | |

| ¢600mm | |||

| ¢750mm | |||

| ¢900mm | |||

| ¢1050mm | |||

| ¢1200mm | |||

| Flow port type | ¢450mm | ||

| ¢600mm | |||

| ¢750mm | |||

| ¢900mm | |||

| ¢1050mm | |||

| ¢1200mm | |||

| ¢1300mm |

3) Accessories:

| Name | Type | Specification | Remarks |

| Accessories | Pilot guide bit | 102 | |

| Guide plate | 102 | ||

| Positive pull head | 102 | ||

| Negative pull head | 102 | ||

| Transfer case | 80T | ||

| Short sub | 102 |

4) Others:

| Name | Specification | Remarks | |

| Slurry System | Slurry mixing system | 5 cubic | |

| Instrument | Exploratory apparatus | F5 | DCI |

| GL600 | Gemdale | ||

| GL700 | |||

| Detecting instrument | 8000 | Reddy | |

4.The whole machine appearance and transportation

Overall dimension 11610×2800×3115mm

Shipping weight (Don’t include drill pipe, drill) 21T

5.The accessory technical documents

The following technical documents are provided for XZ680A horizontal directional drilling rig

Certificate of conformity

XZ680A operation instructions

6LTAA8.9-C325 engine operation instructions and warranty card

BW-600 slurry pump operation instructions

Wearing parts and spare parts list, the accessory tools list

Engineering vehicle air conditioning general specification

Note: The products will be improved along with the technical advancement and the difference will be defined during ordering.

More photos