XZ13600 XCMG Trenchless Horizontal Directional Drill Rig Machine HDD Drill Machine

Enquiry Now!XZ13600 XCMG Trenchless Horizontal Directional Drill Rig Machine HDD Drill Machine

XZ13600 HDD used modularize design and separated main machine, structure adopts crawl chassis, control house is available. It uses the power saving closed hydraulic system, equipped with electro-hydraulic proportion control, efficient advanced load sensitivity.

The main technical specifications reach the leader level in international. The main components of hydraulic system, transmission, electric system and gearbox are made of world first-class brand products, good performance, good reliability.

1. Features Introduction of XZ13600 HDD

1.1 Numerical meter display the working torque, push or pull force and so on parametric in working conditions. Electronic sensor has rapid reaction and can show overload immediately. It also endures accuracy and delay of the traditional hydraulic meter’s indication. It solve the matter to depend the operator to calculate the torque and force by the equipment’s switch directive.

1.2 Equipped with closed energy-saving circuit, load sensing control, electro-hydraulic proportional control and other advanced technology, Using the international famous brand components, reliable quality.

1.3 Four power system, any engine start can complete all the action of the vehicle. Cummins Engine, powerful, ample power reserves to meet drill construction in different working conditions.

1.4 Drill frame adjust by cylinder, work angle change more easy, safe.

1.5 The clamp has two group with eight cylinder clamping so that drill pipe clamping reliable and shackle torque is enough. Full floating clamp, acrossdiameter is φ400mm, clamping and reliable.

1.6 Sliding, rotating system multiple output, modular common rail fuel system and electronic control module, system energy saving, high efficiency of construction, efficiency increased more.

1.7 Modular combination and disassembly and transportation technology, chassis, drill frame, carriage can be disassembled. Power station, operating room meet container transport specifications, transport convenient, low cost.

2. Technology Introduction

2.1 Chassis

XZ13600 HDD adopts crawl chassis. It can fitted to more kind of ground and has high reliability. The travel gearbox producing by world first-class brand make it possible of good performance, good reliability.

| Length of track | 6140 mm |

| Width between two tracks outside | 3400 mm |

| Width of track | 700 mm |

| Distance between wheel’s axis | 5175 mm |

| Number of track roller | 12×2 |

| Gearbox of travelling | Rexroth GFT110×2 |

| Drive force | 385kN |

| Gradient | 30° |

| Travelling speed | 1km/h |

| Ground pressure | 1km/h |

2.2 Engine

Power unit: the powerful engine has the turbine torque increment characteristic is made by Cummins. It meets for the request of China Stage III.

| Model of engine | QSZ13-C550 |

| Rated power | 4× 410kW/(1900r/min) |

| Max torque of engine | 2300 N·m /(1200~1700r/min) |

| Rated speed of engine | China Stage |

| Capacity of fuel | 3000L |

Engine on chassis.:The powerful engine has the turbine torque increment characteristic is made by Cummins. It meets for the request of China Stage III

| Model of engine | QSB5.9-C210 |

| Rated power | 154kW/(2200r/min) |

| Max torque of engine | 820N·m /(1400r/min) |

| Rated speed of engine | 2200 r/min |

| Emission of engine | China Stage |

| Capacity of fuel | 170L |

Rotation adopts the open hydraulic system. The movements of push or pull adopt load sensitivity technology. World first-class brand’s components can provide good performance and good reliability.

1)Rotation system

| Pump | 5× Rexroth A11L 260 |

| Rate of flow | 2470L/min |

| Pressure | 350bar |

| Motor | 6×Rexroth A6VM200 |

2)Push and pull system

| Pump | 6×Rexroth A11L260 |

| Rate of flow | 2964L/min |

| Pressure | 350bar |

| Motor | 16×Rexroth A6V M200 |

| Main valve | AMCA PR-3211-B05 |

3)Clamp system

| Pump | Rexroth A11L260 |

| Rate of flow | 320L/min |

| Pressure | 350bar |

| Clamp clyinder | 8×220 |

| Clamp valve | AMCA PR-3211-B05 |

4)Push and pull system

| Pump | Rexroth A11L190 |

| Rate of flow | 399L/min |

| Pressure | 350bar |

| Motor | 2×Rexroth A2FE125 |

| Manual reset relay | AMCA APV22 |

| 5)Assistant system | ||||||

|

||||||

| 6)Cooling system | ||||||

|

2.4 Electronic system

The HDD adopts intelligent and CAN bus control technology. The meter shows clearly and easy to see.

The HDD shows the actual torque and push or pull force immediacy in the large and high showing size monitor automatic.

PLC control technology can detect the engine speed, the temperature of cooling water, the pressure of lubrication, the temperature of hydraulic oil, the pressure or stoppage of filter element, the position of carriage etc. It can also alarm to the operator in wrong condition.

The HDD travel safety at stepless speed regulation and controlled by wire cable.

| The multi-speed control of rotation and push or pull make HDD be suitable to the complex | |

| geology. | |

| Voltage of electronic | DC24V |

| Battery | VARTA 6-QW-120B |

| Controller | Rexroth |

| Monitor | MURPHY |

| Handle of rotation | P+G |

| Sensor of speed | Rexroth |

| Switch of sensor | Honeywel |

| Switch of route | Honeywel |

| Sensor of temperature | Danfoss |

| Sensor of pressure | Danfoss |

2.5 The entry angel is changed by adopting the link weldment and cylinder. It has the advantage of simple and safety.

The drill frame is made by high tension steel. The pipe support is used in adding or take off the pipe. It is easy to operation and clip. It is convenient for the reason of the drill frame slide by the cylinder.

| The distance of the drill frame slid | 3000 mm |

| The length of the drill frame | 18600 mm |

| Entry angle adjust by drill frame | 8~16° |

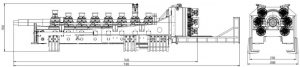

2.6 Carriage

Push or pull is executed by rack and pinion. The HDD also use the floating axis to protect the pipe’s thread. The rapid speed is carried out by the variable motor. The speed of carriage and the force of push or pull can be executed steplessly.

| Push/pull force | 1360kN |

| Carriage speed | 32m/min |

| Torque | 260000N·m |

| Spindle speed | 100r/min |

| Distance of carriage moving | 12000mm |

| Gearbox of rotation | 16×Brevini S600L3 |

| Gearbox of rotation | 6×Brevini ED2250 |

2.7 Clamp

The HDD is fitted with the clamp so that the pipe can be gripped tightly. The clamp can move from the end of drill frame to another end of the drill frame. And it can do great good to operation in cathead condition. The fixed wise and rotation wise can separate or integrate. It has a good sight of clamp and is good to change the tooth.

| Torque of clamp | 450000N·m |

| Rotation angle | 15° |

| Distance of clamp separation | 400mm |

| Across diameter | φ400mm |

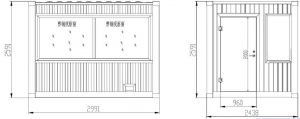

2.8 Control room (optional)

Independent control room, with air condition can lift and go down by cylinder. It is also fitted with light, windscreen wiper, sunshade curtain, damping seat and suit for operation. All these increase comfortable while operating the HDD.

| Import Voltage | AC 220V |

| Length of control room | 2991/5982mm |

| Width of control room | 2438mm |

| Hight of control room | 2591mm |

2.9 Loader Crane(optional)

The HDD is assembled 10t Loader Crane. It was controlled by hand and It operate vey convenience.

Weight of lift 10t

2.10 Pipe and tools (optional)

Petrol pipe and No-dig pipe is available. Water wing backreamer, expander backreamer, compact fluted backreamer or the others special tools is available. The diameter is 400mm to 2000mm, The max distance which can deal with is 2500m. The customer should determine what kind of tools, joint, swivel will be used depend on the geology at the operation site.

| Diameter of pipe | φ219/φ254mm |

| Length of pipe | 9600mm |

| Joint of pipe | HY77 |

Note. The force and torque on the pipe can’t reach to max at the same time. Please to obey the rules of the pipe. This can avoid the thread cement of the pipe.

3. Main technical parameters

| Item | Unit | Parameter | ||||||||

| Power house Engine | Manufacturers | Cummins | ||||||||

| Type | QSZ13-C550 | |||||||||

| Rated power | kW/(rpm) | 4×410/1900 | ||||||||

| Mainframe Engine | Manufacturers | Cummins | ||||||||

| Type | QSB5.9-C210 | |||||||||

| Rated power | kW/(rpm) | 154/2200 | ||||||||

| Thrust-Pull | Max thrust-pull force | kN | 13600 | |||||||

| Max thrust-pull speed | m/min | 32 | ||||||||

| Rotation | Torque | N·m | 260000 | |||||||

| Max spindle speed | r/min | 100 | ||||||||

| Pipe | Diameter × Length | mm | Φ219/Φ254×9600 | |||||||

| Max inclination angle | ° | 16 | ||||||||

| Loader Crane | Lifting weight | t | 10 | |||||||

| Loading capacity | t•m | 25 | ||||||||

| Travel driving | Type | Steel crawel self-propelled | ||||||||

| Traveling speed | km/h | 1 | ||||||||

| Gradeability | % | 30 | ||||||||

| Mainmachine dimension | mm | 20000×3400×4700 | ||||||||

| Mainmachine Weight | t | 135 | ||||||||

| Power house dimension | mm | 9117×2438×2591 | ||||||||

| Power house Weight | t | 26.5 | ||||||||

| Handling room(option) | mm | 2991/5982×2438×2591 | ||||||||

| Handling room Weight | t | 3 | ||||||||

4. Core parts subsidiary

| Name | Manufacturer |

| Engine(Power house) | Cummins |

| Engine(Mainframe) | Cummins |

| Pump | Rexroth |

| Main valve | AMCA |

| Push Motor | Rexroth |

| Push reducer | Brevini |

| Rotary Motor | Rexroth |

| Rotary reducer | Brevini |

| Handle | P+G |

| Walking pump | Rexroth |

| Walking valve | AMCA |

| Walking speed reducer | Rexroth |

| Walking motor | Rexroth |

| Loader Crane | |

| Hydraulic tubing |

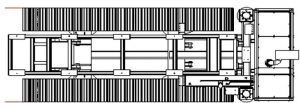

5. The Machine Appearance and Transportation

| The machine work Dimension | 22500×3400×7000 |

| The machine transportation Dimension | 20000×3400×4700 |

| Shiping weight(free of Drill and Drilling Tools) | 126t |

| Power house weight | 26.5t |

| Handling room weight | 3t |

6.Transport program

To meet the requirements of highway transportation, apart for the transport of three parts: upper part of the truck and Chassis. Chassis includes Engine, Hood, Cab, link weldment, Fuel Tank. Two part of the truck includes Drill Frame, Clamp, Anchor, Loader Crane etc.Other is carriage.

| Dimension of the Carriage(L×W×H) | 9300×2080×1960 |

| Weight | About 50t 48t |

![]()

| Dimension of the Drill frame(L×W×H): | 20500×3400×3150 |

| Weight: | about 50t |

Dimension of the Chassis(L×W×H):7150×3400×1945

Weight: about 28t

7. Accompanied Attached Documents

XZ13600 HDD machine start when accompanied by the packing list, include the following technical documents

Product certificate

Product Manual

Engine Specification

Operation and Maintenance Manual of Loader Crane

Packing List (including wearing parts and spare parts inventory, vehicle tools inventory, shipping list with items)