Repair of Kalmar DRT450 Reach Stacker Sudden Automatic Shutdown

Description of failure

A Kalmar DRT450 reach stacker (configured with Volvo TAD1350VE engine) sometimes suddenly stalls during operation, no fault code appears, and the KID display is normal. After the engine is turned off, it is sometimes restarted immediately, and the engine can run normally; sometimes it takes a few minutes of rest to start normally (at this time, the engine cranks normally but cannot be successfully started, and it must take a few minutes of rest).

Troubleshooting

According to the fault phenomenon described by the reach stacker driver, there are mainly two common fault reasons for the sudden automatic shutdown of the engine, one is the fuel or the intake and exhaust system, and the other is the circuit. According to the working principle of the fuel system of the engine, if the fuel system has the phenomenon of air intake, the locomotive should be difficult to start after the automatic shutdown, or the engine is weak during operation, and the fuel system is low pressure (94/01, 94/03, 94/05). ) and other phenomena, the automatic flameout caused by insufficient intake air when the engine is working under load will also show the phenomenon of insufficient power.

The maintenance staff communicated with the driver in depth to understand the situation when the locomotive was turned off. According to the driver’s report, whether it is a day shift or a night shift, when the locomotive is driving in reverse gear while the load is lifted, or when the locomotive is running with no load (in this case, the fault codes 61/03, 61/04, 42/04, 42 appear before the engine is turned off). /05), when the box is suspended in place, it will automatically turn off the flame.

The maintenance personnel first considered that the diesel tank or the oil pipe was dirty and blocked, which would cause the engine to stall, so they checked the oil path from the diesel tank to the additional diesel pre-filter installed on the front fender. First open the top cover of the filter element, and find that the oil spills too slowly (the state of the fuel tank is full and the diesel tank cover is opened), indicating that the fuel outlet of the diesel tank or the oil pipe to the pre-filter element may be blocked. Disassemble the oil inlet pipe of the filter element, oil seeps out but the flow is small. Disassemble the oil pipe joint of the oil outlet of the diesel tank, and the diesel oil is sprayed out in large quantities, indicating that the oil outlet pipe of the diesel tank is blocked. Replace the fuel pipe and empty the oil circuit system, and the test run is normal.

However, after the locomotive was running normally for a period of time, the driver reported that the engine of the locomotive would suddenly and automatically turn off occasionally when driving in reverse gear. After turning off the engine, it will take some time for the locomotive to start again before it can operate normally.

According to the above fault phenomenon of automatic shutdown when reversing, it is judged that the electrical problem of the engine is likely to cause a failure. It is guessed that the sudden shutdown of the engine is caused by the abnormal power supply of the engine controller (D794) caused by the reversing light during reversing. Check the relevant electrical drawings of the DRT450 locomotive and analyze the cause of the sudden flameout.

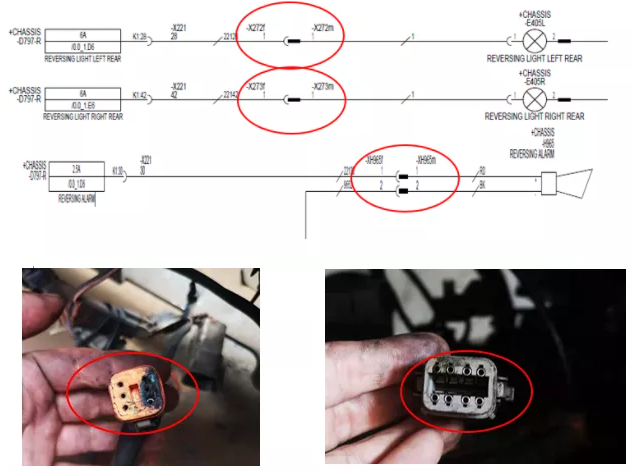

When the locomotive is reversing, the reversing light and reversing buzzer work. The reversing work light and reversing buzzer are powered by the D797-R controller. Then check the reversing light, reversing buzzer wiring and connectors.

After inspection, it was found that the left and right reversing light connectors were ablated and short-circuited. After replacing the connector, the locomotive was arranged to continue to be used, but the automatic flameout failure still existed after a period of use.

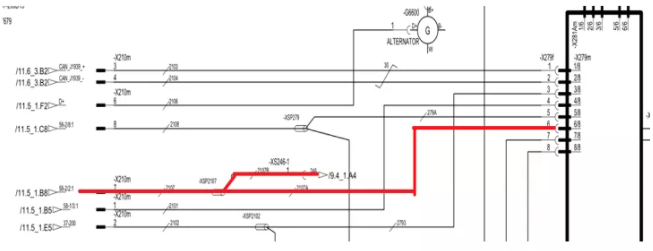

Further check the power supply system of the engine control unit, check the 8-pin connector X279f of the engine control unit wiring harness:

No. 4 pin — (F58-1/3: 1 engine control unit EMS2 battery power supply) voltage is normal 25V; No. 5 pin — (F58-2/8: 1 engine control unit EMS2 ignition power supply) voltage is normal 25V; No. 6 Pin — (F58-2/2: 1 engine control unit EMS2 flameout signal) voltage is normal 25.8V.

At this point, troubleshooting is deadlocked.

What causes the engine to automatically shut down? Low water level protection? Because the locomotive is automatically turned off after a period of use, the engine protection shutdown is automatically turned off after a fixed delay time, and the low water level fault will have a fault code, so this reason can be ruled out. Ignition key switch? However, the KID in the cab did not go out after the engine was turned off, and this reason can also be ruled out. In addition, the engine flameout is caused by the loss of voltage through the EMS flameout signal line of the 6th line of the 8-pin plug X279f, which causes the engine flameout. What is the reason for the loss of pressure on Line 6 under normal use?

According to the above electrical control schematic diagram, the pressure switch circuit on the air conditioner drying bottle was checked, and no abnormality was found.

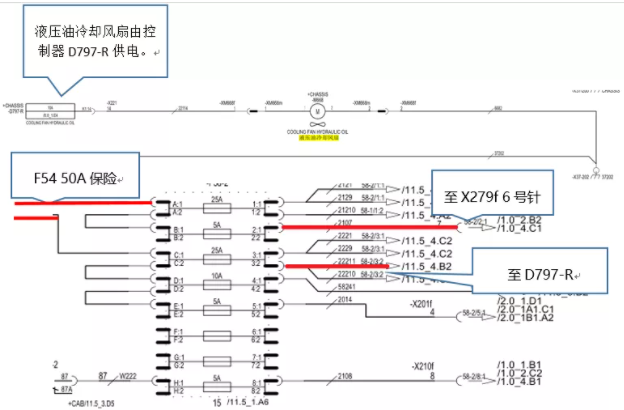

Looking back, the phenomenon of the engine automatically shutting off mostly occurs after the locomotive has been running for a period of time, indicating that the locomotive is in a hot state. The maintenance personnel operated the locomotive on site to heat up the engine and hydraulic system. When the temperature of the hydraulic oil reached 65°C, the cooling fan of the hydraulic oil turned and the engine was automatically turned off. When the ignition key is manually reset and restarted after the ignition is turned off, it cannot be started (the hydraulic oil cooling fan is still rotating at this time). When the hydraulic oil cooling fan stops running, the engine starts normally. When it heats up again, the engine shuts off immediately when the hydraulic oil cooling fan turns.

Further check the voltage of pin 6 of the 8-pin plug X279f when the hydraulic oil cooling fan is started, and the voltage drop is obvious when measured by the test lamp.

Check the hydraulic oil cooling fan, no obvious short circuit phenomenon is found in the cooling fan. Try to replace the new fan and test the machine, but there is still an automatic shutdown fault.

Further check the relevant circuit diagram of the hydraulic oil cooling fan for analysis and inspection.

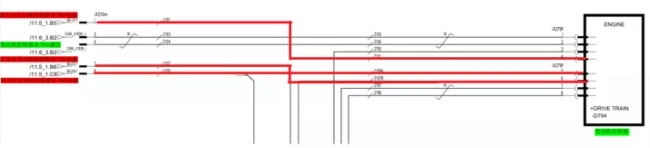

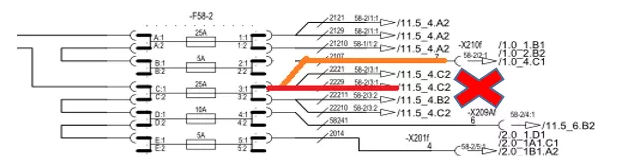

Check the circuit according to the above circuit diagram, and found the fault point: the locomotive has artificially connected the line of No. 6 pin of X279f to the power supply line of D797-R, as follows:

Workaround

According to the circuit diagram of the original car, connect the X279f No. 6 pin power cable back to the F58-2/2:1, and the test machine is normal.

Case Summary

1. After the engine is started, the F58-2/2:1 fuse normally supplies power to the No. 6 pin of the X279f socket of the engine controller, but the No. 6 pin of the X279f socket is wrongly connected to the power supply of the D797-R. After the locomotive is turned on the air conditioner, the power consumption increases, and the current of the hydraulic oil cooling fan is relatively large when the hydraulic oil cooling fan starts, which instantly reduces the voltage of the F58-2/3:1 fuse, making it lower than the threshold of the engine shutdown signal, thus causing the engine to stop. Automatically shut off.

2. Why does a series of gearbox fault codes 61/03, 61/04, 42/04 and 42/05 appear when the locomotive is turned off? The reason is that the locomotive has been running normally. When the engine suddenly turned off, the gearbox controller received the missing signal from the engine speed sensor, but the locomotive was still coasting, which caused the gearbox controller to send out the above-mentioned speed sensor, clutch slip, etc. error code.

3. The Kalmar DRT reach stacker has just replaced the whole vehicle wiring harness before this fault occurs. The electrical systems of Kalmar equipment are all computer-controlled, and some of the most common electrical components, including switches, bulbs and fans, are controlled by controllers for more comprehensive monitoring, management and diagnostics of the electrical system. Therefore, it is recommended to use the original parts provided by regular channels when maintaining and replacing the main key components of the equipment. Secondly, if the maintenance personnel are not clear, they should avoid jumping over or changing the electrical circuit of the original car at will, so as to avoid abnormal operation of the electrical system, or even damage to the control unit or fire accident.